Just like smartphones and other smart technologies, smart manufacturing refers to the integration of advanced technology into traditional production and manufacturing workflows. Folding artificial intelligence, machine learning, the internet of things (IoT), and automation into these traditional manufacturing processes creates a highly dynamic, adaptable, and productive factory.

This continual merge of technology and manufacturing is also referred to as Industry 4.0, or the fourth industrial revolution.

By understanding the technologies being incorporated into traditional workflows as a part of Industry 4.0, organizations can start to plan their own integrations. In turn, they create their own smart manufacturing processes fitted to their own needs.

Learn about the most common obstacles organizations face when adopting a new technology in Impact’s webinar, Why Your Tech Rollouts Fail (and What to Do About It).

What Is Smart Manufacturing?

Smart manufacturing is a term used to describe the digitization of the manufacturing processes, including supply chains, production, logistics and distribution, sales, and stocking. It’s made up of many unique technologies and solutions that each play a role in the production process.

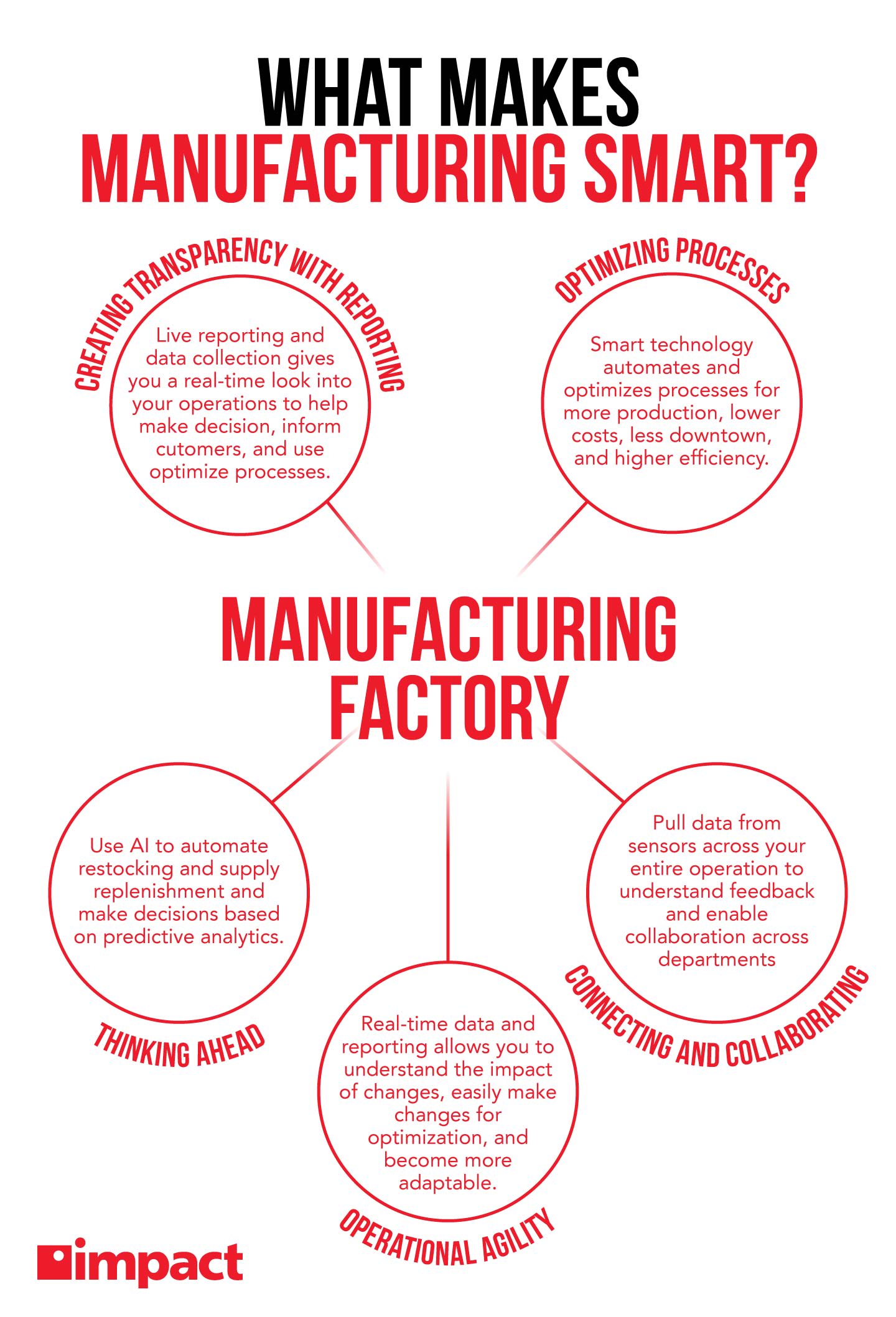

Smart manufacturing utilizes the internet of things and industry 4.0 to connect these technologies, equipment, and software. Afterward, this tech works together to record, report, and analyze data streams using AI, machine learning, and automation to make more accurate predictions and decisions.

This connectivity and collaboration between machines helps streamline supply chains, inventory management, production, and distribution.

Connecting operations and helping manufacturers stay on the cutting edge of technology while becoming more efficient, productive, and competitive in their market is the pinnacle of Industry 4.0.

The Technologies that Make Up Smart Manufacturing and Industry 4.0

As mentioned above, smart manufacturing is made up of many different types of modern technologies.

Here are three of the most common smart manufacturing technologies and a look at how they streamline and optimize processes in the manufacturing space.

1. AI and Machine Learning

These technologies act as the digital brains behind connected factories—analyzing real-time data from sensors, machines, and systems to spot inefficiencies, predict maintenance needs, and automate decision-making.

For example, instead of halting production when a machine fails, predictive maintenance algorithms can flag early signs of wear and tear, allowing for timely repairs that minimize downtime and reduce costs.

Beyond maintenance, AI enhances quality control and supply chain agility. Vision systems powered by machine learning can detect minute defects in products far more accurately than the human eye, ensuring higher consistency and fewer recalls.

On the operations and logistics side, AI models crunch through historical and real-time data to fine-tune production schedules, manage inventory dynamically, and respond to shifts in demand with precision. The result is a leaner, more responsive manufacturing ecosystem—one where waste is minimized, productivity is maximized, and employees are empowered to focus on higher-level tasks.

2. Automation

Automation is the powerhouse of Industry 4.0, transforming traditional manufacturing lines into streamlined, self-regulating systems. By integrating advanced robotics, intelligent control systems, and real-time monitoring, automation reduces the need for manual intervention in repetitive or hazardous tasks.

Robots now work alongside humans with incredible precision—assembling, welding, packaging, or inspecting parts at speeds and accuracy levels that boost output and consistency. This shift not only accelerates production but also improves worker safety and reduces error rates dramatically.

What makes automation in Industry 4.0 even more impactful is its ability to adapt and optimize on the fly. Smart systems can instantly adjust operations based on sensor feedback or changing production goals, rerouting tasks, reallocating resources, or even tweaking processes for efficiency without halting the line.

This level of agility slashes downtime, trims waste, and ensures continuous improvement. In essence, automation acts like the cogs that connect all your smart processes.

3. Cloud

By moving data storage and computing power off-site, the cloud eliminates the need for bulky on-premise infrastructure and allows real-time access to critical production data across facilities, suppliers, and partners. Engineers, managers, and decision-makers can monitor performance dashboards, collaborate on product designs, or troubleshoot issues remotely—all through secure cloud platforms.

This real-time visibility also empowers smarter, faster decision-making. Cloud-based analytics tools can aggregate massive amounts of data. These tools allow you to take data from machine performance and energy use to inventory levels and customer demand and turn it into actionable insights.

Insights that help optimize workflows, forecast supply chain disruptions, and streamline everything from procurement to delivery. In short, cloud technology doesn’t just connect the factory—it transforms it into an intelligent, data-driven ecosystem where every process is more efficient, coordinated, and future-ready.