More and more businesses are implementing automation into their operations to help bring in more efficiency and productivity, but that often leaves people wondering where their place may be in a automated future and asking the question: Will supply chain management be automated?

Much of modern automation in supply chain management removes roadblocks from human workers and is beneficial to their work as an aid, removing tasks that can be done by robots and leaving tasks that require human intervention and decision making.

In this blog, we’ll be talking about how automation is used in supply chains today, asking whether supply chains will be automated in the future, and what the effects will be on current human workforces.

How Automation Is Used in Supply Chain Management

Automation in supply chain management, much like automation in most other areas of business, should really not be thought of as something to replace employees, but rather to aid them in either their decision-making capacity or the amount of time they must spend performing manual tasks.

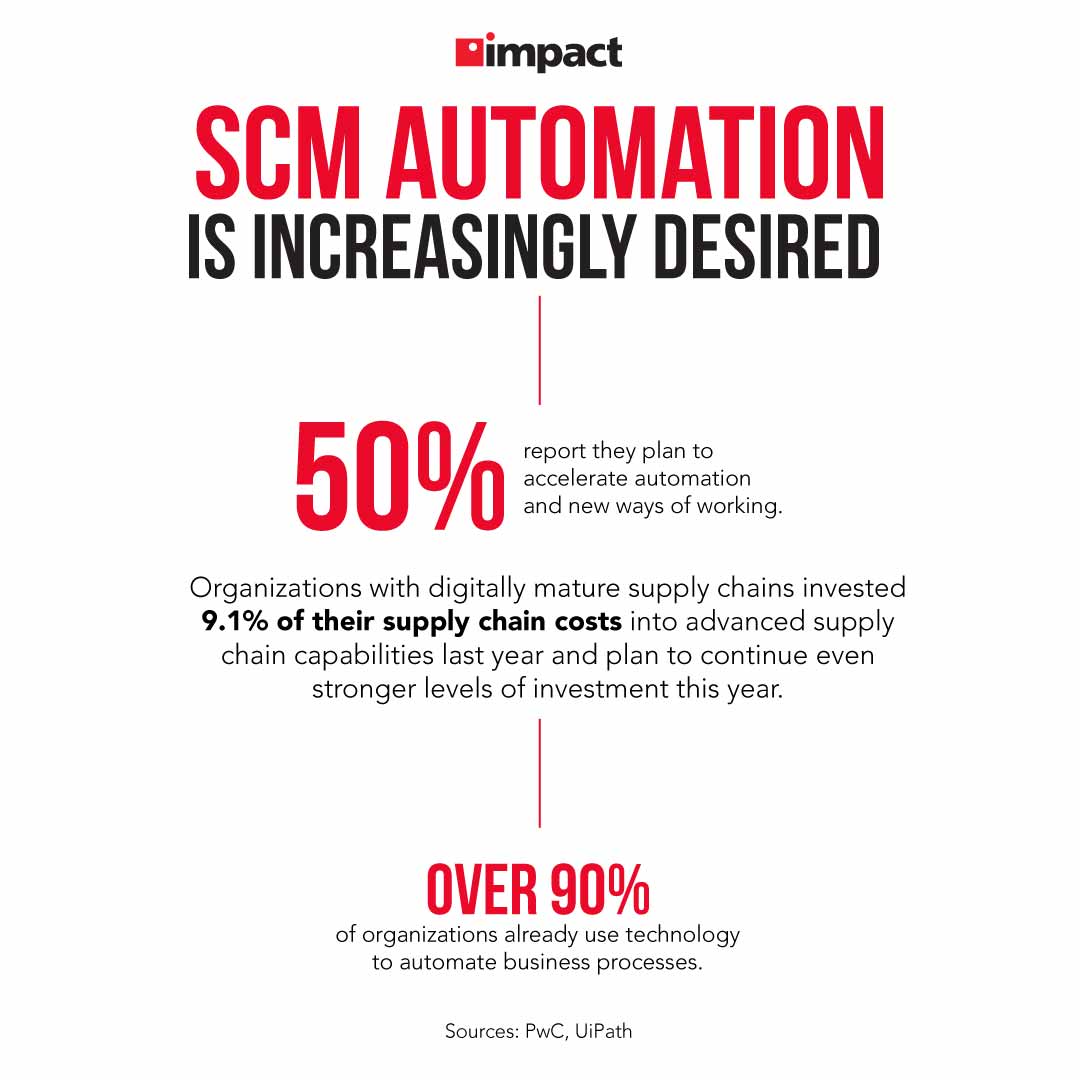

50% of organizations report they plan to accelerate automation and new ways of working.

What Are the Benefits of Supply Chain Automation?

Not only does automation help improve productivity by working 24/7 without breaks, it also reduces human errors and improves a company’s ability to remain in compliance with new and emerging laws regarding data compliance.

Examples of this would be HIPAA for healthcare providers or CMMC for manufacturers.

Related Post: What is CMMC?

Automated storage and retrieval systems can increase order accuracy by up to 99%

Automated Robots Handle Repetitive, Predictable Tasks and Roles

One way automation is changing the landscape of jobs within the supply chain is by removing the need for humans to complete the menial, repetitive tasks that are less skill-based.

Instead of performing these tasks directly, roles have changed to managing these automation robots and systems that do it for them, with staff instead focusing the bulk of their time on non-automatable tasks instead.

Automation can handle tasks in a variety of areas within the supply chain, from inventory to shipping to the back office.

Tasks like data entry, process tracking, picking, inventory management, and procuring documents can all be automated to some degree through software and hardware bots.

As far as software bots are concerned—which are the primary means through which organizations today automate their processes—virtually anything with a rigid flow of data can be automated.

This makes automation perfect for the aforementioned manual tasks, but not so much for anything that expressly requires a level of human input to perform.

Automation Improves Human Work

Automation is most effective when collaborating with the human workforce by taking away those repetitive jobs and allowing humans to focus on work that requires a human touch in the form of decision-making, critical thinking, creativity, analysis, and other things that robots cannot do.

An example of this is customer service. All throughout the supply chain process, customers need to be updated, informed, and listened to.

If they have questions about their order (where it is, when it’ll arrive, purchase information, etc.), it should be answered as quickly as possible.

Typically, this would mean a customer service representative combing through potentially thousands of inquiries and answering each one.

With automation, a robot can handle some of the simple inquiries like shipping updates and send more complicated questions and comments to a human.

- 90% of employees are burdened with menial tasks which can be easily automated with technologies like RPA, which translates to a lot of lost time and money.

This drastically cuts down on the time a customer must wait before being served and improves the overall customer experience as employees are able to dedicate more of their time to them.

Robots Help Us Make Better Decisions

One of the main ways that robots and automation can help people become better at their jobs and elevate their work is by providing us with organized information to make better decisions.

Rather than spending so much time collecting and organizing data, people can spend it on analysis and building data-driven strategies based on informed decisions to better optimize processes and improve operations.

Bots are extremely useful for automating workflows, but they have the additional benefit of being able to make calculations in a fraction of the time it would humans to, meaning numbers can be crunched in an instant, and real-time insights can be provided to the appropriate stakeholders.

For example, if a manufacturer has a sensor on a machine for the purposes of maintenance, predictive analytics can be employed to read raw data fed by the machine and recognize when it needs repairs.

The global predictive analytics market size is expected to grow from $10.5 billion in 2021 to $28 billion in 2026 at a CAGR of 21.7%

This particular use case is something that is heavily pursued by many organizations that deal with machinery and is an excellent way of reducing costs, all through automation—this principle of leveraging bots to provide actionable data can be adopted in many lines of business, including marketing and sales, administration, and finance, among others.

McKinsey research suggests that, on average, companies that aggressively digitize their supply chains can expect to boost annual growth of earnings before interest and taxes by 3.2%—the largest increase from digitizing any business area—and annual revenue growth by 2.3%.

More Process and Operations Transparency

A more transparent supply chain helps workers and customers alike as more information is available to track orders, manage inventory, and better understand the efficiency of processes.

Supply chains face certain levels of uncertainty every day which, before the implementation of automation and other digital technology, left workers without proficient information on the progress of orders or inventory.

This new technology fills in the gaps between steps in the process and creates a central, accessible location for all of your data.

This helps give workers more certainty when making decisions with real-time updates and information.