Lean manufacturing definition: What is lean manufacturing? The core principle of lean manufacturing refers to the practice of reducing waste and improving productivity, helping organizations offer a better product or service more efficiently to their customers.

Though the concept of lean manufacturing has been around since the 1930s, the ideas behind it are still relevant today and widely practiced, particularly with the advent of affordable digital technology for small and midsize businesses.

Japanese auto manufacturer Toyota is credited with coming up with the concept, focusing their efforts on two distinct aspects:

- Jidoka: Refers to the process of human oversight of technology—automation with human assistance.

- Just-in-Time: Refers to improving productivity by creating only what is needed, when it is needed, and in the quantity needed.

Naturally, most manufacturing businesses will be familiar with the concept of just-in-time production, but it’s applicability in the context of modern technology has never been more apt.

Today, we’ll be taking a look at the key areas of lean manufacturing and how technology can help address these areas.

Core Methods of Lean Manufacturing

What’s makes up a lean manufacturing strategy? There are five core methods of lean manufacturing that attempt to streamline operations as effectively as possible. They are:

1. Improving processes

Any process that where labor is inputted, and an output is expected, comes under this. Of course, this pretty much covers everything, but in manufacturing terms, this would typically be applied to processes that can be improved through automation.

These processes are not restricted to any one department; there are several within any manufacturing company—or any company for that matter—that can benefit by using tech to improve their processes. A simple example would be to automate payment invoices, order fulfillment, or using bulk actions for large orders.

Suggested solution: workflow automation

When we talk about improving processes in an organization, it’s common to pursue automation as a means to do so.

By using robotic process automation (RPA), companies can utilize software bots that are either attended or unattended.

Attended bots require a human to personally trigger the action, whereas unattended bots operate on their own without the need for any input.

By using the appropriate mix of attended and unattended bots, working processes can be streamlined significantly during the manufacturing process, from production to fulfillment.

Related Case Study: New Document Management Procedure Helps Insurance Company Reorganize AP and Claims

2. Identifying value

The value of your product is determined by the value that your customers find in it. While this may seem obvious, a large number of manufacturers fail to dig into the valuable data that their customers provide.

A study by Deloitte shows that many manufacturing enterprises are lagging when it comes to broader enterprise-wide initiatives such as customer-centric innovation and human resources.

In other words, many businesses in the industry are not taking advantage of the technology at their disposal to identify value. When they do, they are able to more effectively assess what works and what doesn’t, providing a better overall product.

Suggested solution: big data analytics

In today’s digitally-driven world, big data makes or breaks organizations.

Data is everywhere, in every facet of our lives, and yet so few businesses leverage this information to help them identify valuable insights for growth.

Of businesses that adopt the cloud, 87% of them report business growth from their cloud use. 41% of businesses are able to directly attribute business growth to their use of cloud services.

Related Post: What Is Smart Manufacturing?

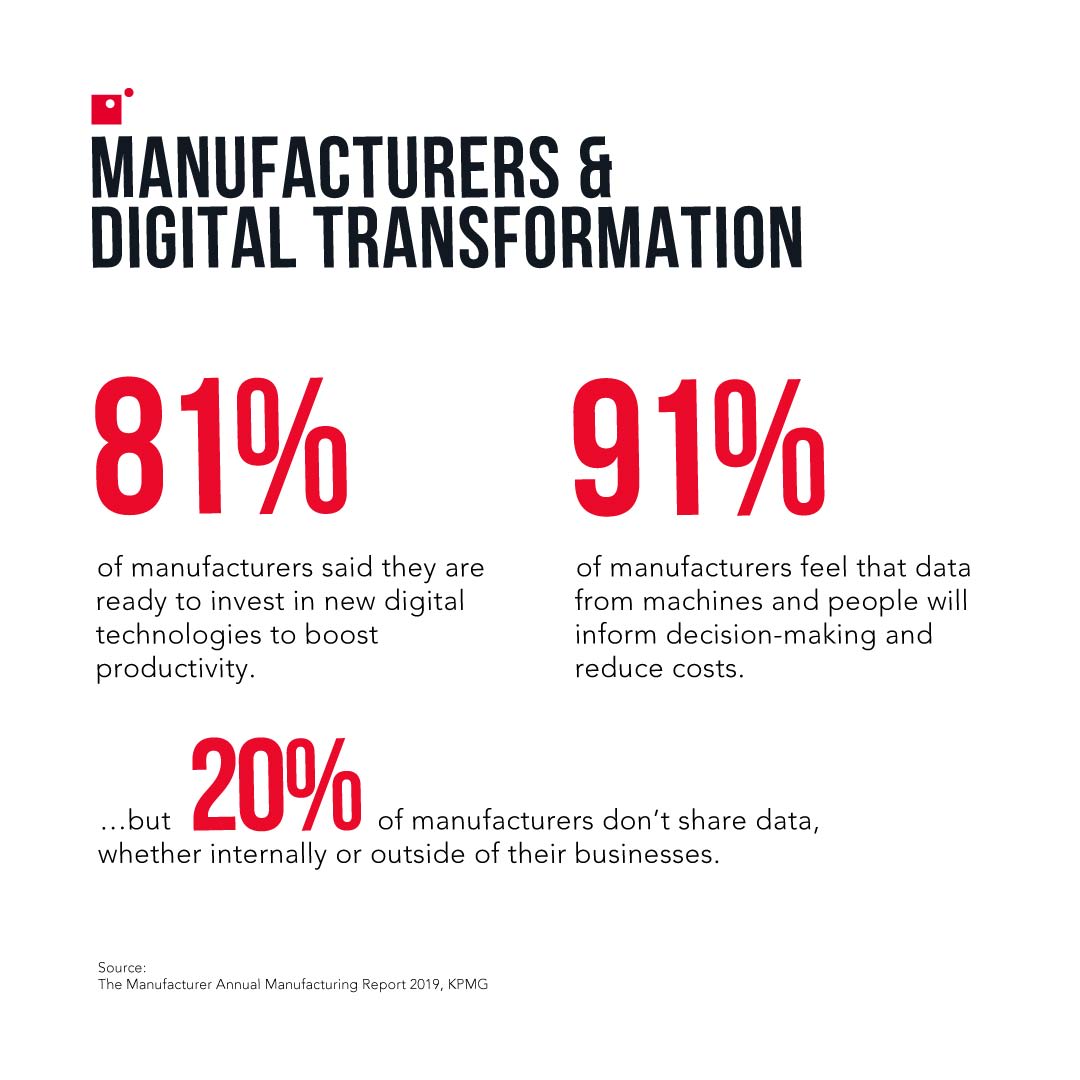

The simple fact of the matter is that while many businesses profess a desire to make more use of their data, the reality is that very few of them do.

Data can be useful for practically any job, whether it’s determining how you can better track inventory levels using predictive analytics, monitoring the health of machines in the production line so problems can be routed out before they become a larger issue, or having the ability to more effectively assess your factory’s efficiency for individual processes.

3. Continually improve

Lean manufacturing today, as with most digital initiatives, is about continually improving your processes, rather than treating it as a one-off solution.

This means that once the technology is in place, like a new ERP system, it should be used to consistently look for issues in product quality and waste, helping the business remove factors—often previously unknown—that are slowing processes.

Suggested solution: Managed IT

Being able to scale tech solutions is important for organizations today. As we continue to move away from the more traditional approach of one-off purchases for software—these systems today are commonly referred to as legacy solutions.

While there’s nothing wrong with legacy solutions per se, software developers and distributors have shifted to cloud-based subscription models for their apps.

Cloud-based solutions offer the best pathway for technology implementation as far as future-proofing is concerned, chiefly because these solutions are very scalable for businesses experiencing growth or decline, alleviating some of the issues that might be present when encumbered with an old system.

Learn more about what a Managed IT program looks like here.

4. Create flow

Flow is highly contingent on improving processes. Flow is when a business improves its processes to the point where an order process, from placement to delivery, runs as smoothly as possible with the tools available.

If there are unnecessary barriers that slow this process down, then your flow is disrupted and you’re losing money, whether it’s through labor costs or the cost of not being able to deliver the kind of service you’d like to.

Suggest solution: process mapping/automation

Establishing good flow begins with understanding exactly how effective your working processes are, which is done through process mapping.

This also ties into automation once more, as after the process mapping is complete, stakeholders can identify where they are having issues with flow and adopt automation as a means to improve it.

5. Standardize processes

Finally, we have standardized processes. It’s impossible to improve your processes and achieve flow if your processes are not standardized to some degree.

Standardization removes guesswork in processes and ensures a defined degree of quality. It also allows you to have a documented system for your processes so you can compare it to your improved processes down the line.

Suggested solution: enterprise resource planning (ERP)

We will go into a little more detail about ERPs later in the post, but ERPs in the context of standardizing processes is extremely important.

This is particularly the case for organizations that still operate with different departments using different solutions that are not connected to one another.

Because of this disconnect, it’s common for businesses to inadvertently create data silos—in effect shutting off their own ability to comprehensively assess their own data across the organization.

Related Post: Breaking Down Data Silos: Unify Your Business Data

By adopting an ERP, companies can integrate all their solutions into a single dashboard, making data accessible at any time from anywhere.

This allows for far more standardization, and is particularly important for businesses that operate across multiple offices or locations.

Eight Wastes of Traditional Operations

In addition, there are the so-called “eight wastes of traditional operations”—that prevent lean manufacturing. These are:

- Unnecessary transportation

- Excess inventory

- Unnecessary motion of people or equipment

- Idle employees or equipment

- Over-producing a product

- Over-processing a product, such as adding unnecessary features that add no value

- Defects

- Workers, in terms of whether they’re being effectively used according to their skillsets

The eighth factor is a newer addition, but is nonetheless an important waste that should be removed.

If any of these wastes are familiar, then it’s time to start considering how you can address these issues and improve the processes with your operations to achieve lean manufacturing.

What’s the Solution to Waste?

Businesses can assess their issues through an audit, either by themselves or through a third party like an MSP.

Once you’ve identified the waste issues that are holding your operations back, it’s time to put in place digital solutions that can help you address them.

Enterprise resource planning systems

An ERP is a must for manufacturing businesses. ERPs are systems that unify data across a business, and can cover a wide range of areas, such as:

- Inventory and supply chain

- Automated reports

- Project management

- Human resource functions

- Sales and marketing

The amount of data in the world, and by extensions in businesses, is truly staggering, but what if you’re not using that data?

Over the last two years alone 90% of the data in the world was generated.

Well, to put it bluntly, the organization as a whole suffers. The key characteristic of a modern ERP platform is its ability to examine big data sets automatically and provide you with actionable data.

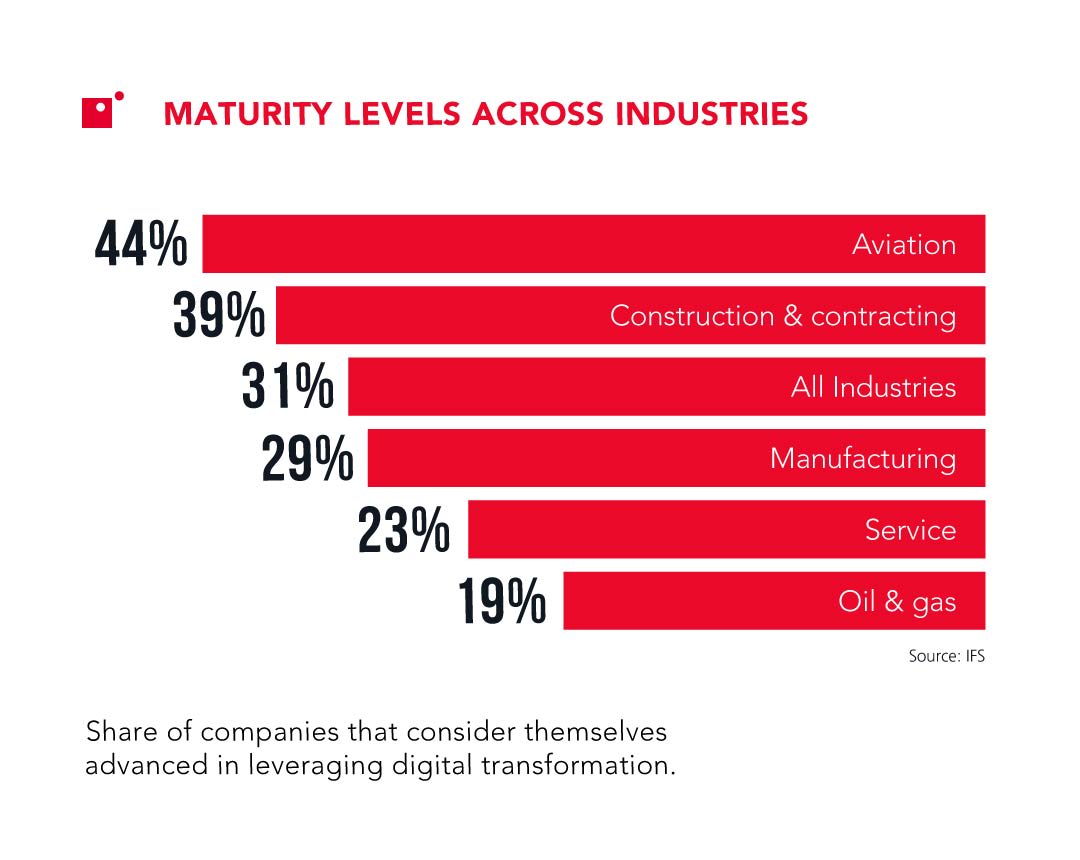

Analyzing data sets has always been a part of manufacturing, but the scale and speed at which it can be done today is unmatched—one of the reasons the use of predictive analysis grew 76% from 2017 to 2019.

For manufacturers, this is crucial for understanding weaknesses and fixing them, creating leaner operations.

For more information about how businesses can use analytics with ERPs to streamline their supply chains, click the related post below and see what the frontrunners are doing to cut waste and implement leaner operations.

Related Post: Supply Chain Disruption: Mitigating Threats Effectively with Analysis

Customer relationship management

CRMs can come either standalone or as a module of an ERP system. Similarly, they use data sets—but relating solely to clients.

Your CRM will be able to give you actionable data on addressing customer satisfaction with your service and product.

By keeping your customer data all in one place and using the tool for analysis, you’re able to better understand what your customers like and dislike and change your service accordingly.

It’ll also give you opportunities to identify upselling and retargeting opportunities within your consumer base, amongst other things.

Bottom Line

If you came here asking, “What is lean manufacturing?”, we hope this blog post gave you an understanding of what it is, how it’s deployed by organizations, and why it’s important for manufacturers today.

Lean manufacturing is a term that has been used around the United States since the late 20th century and it’s as important today as it ever was—just in a very different context.

The principles of cutting waste, improving processes, and streamlining manufacturing operations are hardly new, but the tools with which to achieve these goals are today more viable for SMBs than they have ever been.

There’s a reason organizations across the country are implementing cloud ERP systems and similar modules on a large scale; it’s to take advantage of the wealth of data that companies have at their disposal, and to use that data to drive meaningful change.

If you’re taking a look at the list of wastes, and any of them are ringing true, it’s definitely time to think about getting the correct solutions in place so that you can address the issues head-on, creating a leaner manufacturing operation that will reduce expenditure and maximize productivity.

In light of recent events, many organizations have found themselves playing catchup, trying to implement makeshift cloud solutions to make up lost ground while their workforces see drastic transformations.

To find out more about how the cloud can ensure your business is in good shape for the future, download our eBook, “Which Cloud Option Is Right For Your Business?”